Back-Bored

Back-Bored

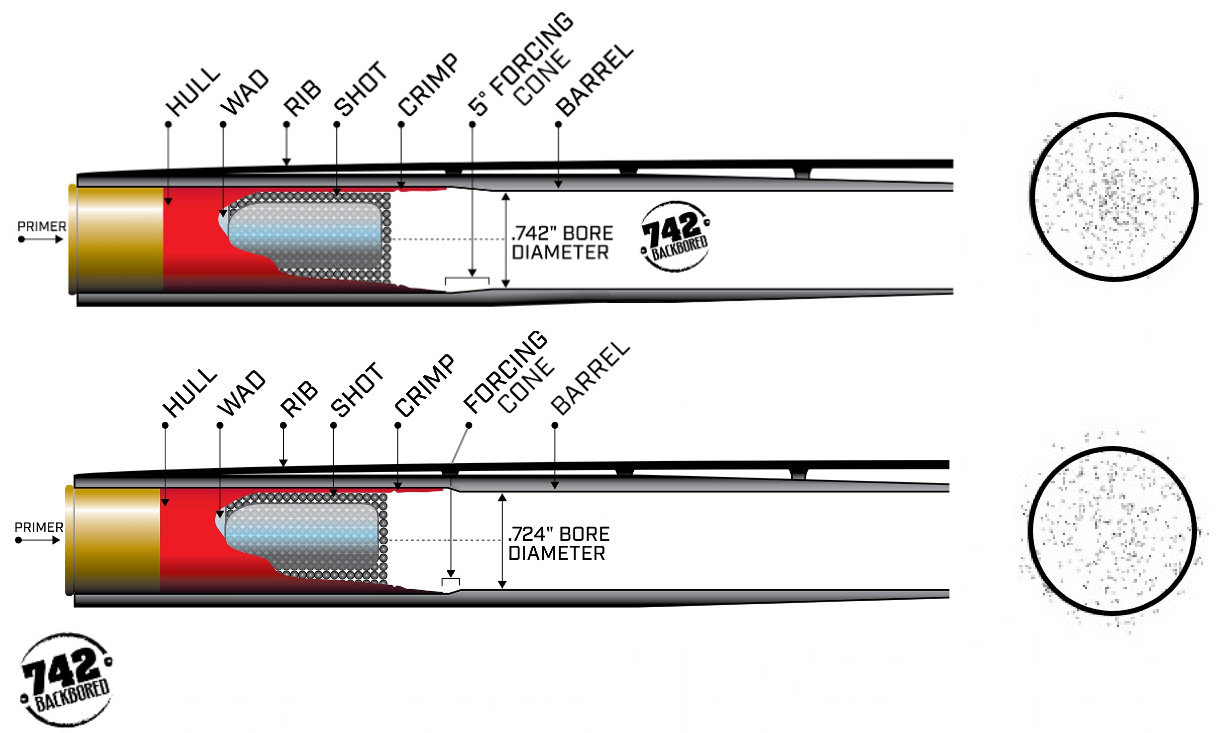

Browning was the first firearms company to offer factory back-boring to shotguns for reduced recoil and improved patterns. Back-boring increases the inside bore diameter to its ideal, maximum allowable specification. This reduces friction between the shot cup and the barrel, allowing the energy developed by the powder to propel the shot pellets to a higher velocity.

Reducing friction from the forcing cone on the shot column also results in fewer deformed pellets for more uniform patterns and keeps more pellets in the center of the pattern. Back-bored barrels work hand-in-hand with the Browning Invector-Plus™ interchangeable choke system.

Extensive research and testing has proven that when it comes to back-boring, .742" is the ideal interior barrel diameter for 12 gauge, ensuring tight, consistent patterns. Any larger and gases blow by the shot cup and reduce pellet velocity. Too small and the pellets are deformed as they pass through the forcing cone, causing poor ballistic performance.

- Back-boring reduces friction between the shot cup and the bore for increased shot pellet velocity, minimized pellet deformity for more uniform patterns and reduced felt recoil. It is standard on A5, Maxus, BT-99 and on 12 and 20 gauge Citori, Cynergy, BPS and Silver models.

- Browning back-bore specifications have been perfected and represent the ideal bore diameter needed to minimize shot deformation and maximize pattern uniformity, consistency and density.

- A larger bore diameter lets gases slip by the shot cup, resulting in reduced pellet velocity and blown patterns. A smaller diameter forcing cone can deform pellets, causing flyers and poor ballistic performance.

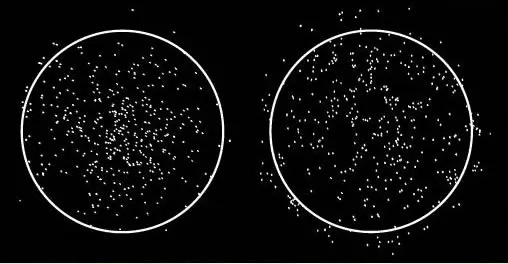

Browning pattern with Back-Bored Technology (left), the competitor's pattern without Back-Bored Technology (right).