Browning BPS Pump Shotgun Owner's Manual

Browning BPS Pump Shotgun Owner's Manual

Important operating instructions for: Browning BPS Shotgun.

If you have any questions about your new firearm, this owner’s manual or other Browning products, contact:

Browning Consumer Information

One Browning Place

Morgan, UT 84050-9326

Phone: (800) 333-3288

browning.com

Please use the space below to record information about your new firearm.

Model __________________________________________________

Serial Number ____________________________________________

Purchased From __________________________________________

Date of Purchase __________________________________________

THANK YOU FOR CHOOSING BROWNING

The Browning BPS is a proven shotgun in the field, marsh and range. Fine workmanship and well-executed design provide a solid, confidence-inspiring feel when working the action and is the reason behind the reputation for rugged dependability the BPS has earned.

With a reasonable amount of care, your BPS shotgun is designed to give you many years of dependable, enjoyable service.

Specifications within this owner’s manual are correct at the time of printing and subject to change without notice.

STATE WARNING

According to state law, California requires that firearm manufacturers, distributors and retailers include conspicuous, specific warnings with firearms sold in that state.

Firearms must be handled responsibly and securely stored to prevent access by children and other unauthorized users.

California has strict laws pertaining to firearms, and you may be fined or imprisoned if you fail to comply with them. Visit the Web site of the California Attorney General at https://oag.ca.gov/firearms for information on firearm laws applicable to you and how you can comply.

Prevent child access by always keeping guns locked away and unloaded when not in use. If you keep a loaded firearm where a child obtains and improperly uses it, you may be fined or sent to prison.

Las armas de fuego deben de ser manipuladas responsablemente y almacenadas en sitios seguros para prevenir el acceso a ellas por parte de niños y personas sin autorización.

California cuenta con leyes estrictas sobre las armas de fuego, y puede ser multado y encarcelado si no las obedece. Visite la página web de California Attorney General, https://oag.ca.gov/firearms para más información sobre cómo cumplir con las leyes de armas de fuego.

Prevenga el acceso de los niños a las armas de fuego manteniéndolas siempre en un lugar seguro, bajo llave y descargadas cuando no estén en uso. Si usted deja un arma cargada al alcance de un niño, y éste la utiliza indebidamente,usted podría ser multado e incluso enviado a la cárcel.

WARNING: YOU ARE RESPONSIBLE FOR FIREARMS SAFETY

WARNING: YOU ARE RESPONSIBLE FOR FIREARMS SAFETY

FAILURE TO FOLLOW ANY OF THE FOLLOWING WARNINGS COULD RESULT IN SERIOUS INJURY OR DEATH.

As a gun owner, you accept a set of demanding responsibilities. How seriously you take these responsibilities can be the difference between life and death.

There is no excuse for careless or abusive handling of any firearm At all times handle this firearm and all other firearms with intense respect for their power and potential danger.

Please read and understand all of the cautions, warnings, notices, proper handling procedures and instructions outlined in this owner’s manual before using your new firearm.

1 - ALWAYS KEEP THE MUZZLE OF YOUR FIREARM POINTED IN A SAFE DIRECTION EVEN THOUGH YOU ARE CERTAIN IT IS UNLOADED. Never point any firearm at anything you do not intend to shoot. Be extremely alert and aware of all persons and property within the range of your ammunition.

2 - NEVER RELY TOTALLY ON YOUR FIREARM'S MECHANICAL “SAFETY” DEVICE. LIKE ANY MECHANICAL DEVICE, A "SAFETY" CAN SOMETIMES FAIL; IT CAN BE JARRED OR INADVERTENTLY MANIPULATED INTO AN UNSAFE CONDITION. The word, “safety,” describes a firearm’s trigger block mechanism, sear block mechanism, hammer block mechanism, or firing pin block mechanism. Mechanical “safeties” are designed to place your firearm in a safer status, and no guarantee can be made that the firearm will not fire even if the “safety” is in the on safe position. Mechanical “safeties” merely aid safe gun handling and are no excuse for pointing your firearm’s muzzle in an unsafe direction. See “Operation of the Safety” section below for instructions on the operation of this firearm’s “safety.”

Remember, safe gun handling does not stop with your firearm’s mechanical “safety” devices, it starts there. Always treat this firearm with the respect that you would a loaded, ready-to-fire firearm.

Some firearms do not have a mechanical safety. Many target firearms, lever-action firearms, and pistols do not have manual “safety” mechanisms. Therefore it is critical to read and understand the owner’s manual for every firearm which explains the safe operation of the firearm.

While it is a good idea to “test” your firearm’s mechanical “safety” periodically for proper function, never test the “safety” while your firearm is loaded or pointed in an unsafe direction.

3 - WHENEVER YOU HANDLE ANY FIREARM, OR HAND IT TO SOMEONE, ALWAYS OPEN THE ACTION IMMEDIATELY AND VISUALLY CHECK THE FIREARM'S CHAMBER TO MAKE CERTAIN THAT THE FIREARM IS COMPLETELY UNLOADED. Make certain the firearm does not inadvertently contain any ammunition. Remember, merely removing the magazine does not mean the chamber is unloaded. Always keep the chamber empty and the “safety” in the on safe position unless shooting is imminent.

4 - ALWAYS WEAR EAR AND EYE PROTECTION WHEN SHOOTING. Unprotected, repeated exposure to gunfire can cause hearing damage. Wear hearing protection (shooting ear plugs or muffs) to guard against such damage.

Wear shooting glasses to protect your eyes from flying particles. Allow proper distance (eye relief) between a scope and your eye when firing a scoped pistol, rifle or shotgun. Do not use unorthodox shooting methods that could cause the rearward travel of the slide or bolt of a firearm to contact your eyes, face or hands. Always keep a safe distance between the muzzle of your firearm and any persons nearby, as muzzle blast, debris and ejecting cartridges could inflict serious injury.

Always wear eye protection when disassembling and cleaning any firearm to prevent the possibility of springs, spring-tensioned parts, solvents or other agents from contacting your eyes.

5 - KEEP ALL FIREARMS UNLOADED DURING TRANSPORT, EVEN WHEN STORED IN A HOLSTER, GUN CASE, SCABBARD, OR OTHER CONTAINER.

6 - DROPPING OR JARRING A LOADED FIREARM CAN CAUSE ACCIDENTAL DISCHARGE. This can occur even with the “safety” in the on safe position. Be extremely careful while hunting or during any shooting activity to avoid dropping any firearm.

7 - HUNTING FROM ELEVATED SURFACES SUCH AS TREESTANDS IS DANGEROUS. Doing so may increase the risk of mishandling a firearm. The following rules should always be observed by you and those you hunt with: Always make certain that the stand being used is safe and stable. Always make certain that your firearm is unloaded when it is being taken up and down from the stand. Always make certain that your firearm is not dropped from the stand, or dropped while it is being taken up or down from the stand. Remember, a loaded firearm may discharge when dropped, even with the “safety” in the on safe position.

8 - STORE YOUR FIREARM AND AMMUNITION SEPARATELY, WELL BEYOND THE REACH OF CHILDREN. Take prudent safeguards to ensure your firearm does not become available to untrained, inexperienced or unwelcome hands. Store all firearms in secure, locked cases or a gun safe. Keep your firearm unloaded when not in use.

9 - BEWARE BARREL OBSTRUCTIONS. Mud, snow and an infinite variety of other objects may inadvertently lodge in a barrel bore. It only takes a small obstruction to cause dangerously increased pressures that can damage your firearm and cause serious injury to yourself and others..

BEFORE CHECKING FOR A BARREL OBSTRUCTION, BE CERTAIN YOUR FIREARM IS COMPLETELY UNLOADED, THERE IS NOT A LIVE CARTRIDGE IN THE CHAMBER AND THE “SAFETY” IS IN THE ON SAFE POSITION.

After assuring yourself that the firearm is completely unloaded, open the breech or action and look through the barrel to be sure it is clear of obstructions. If an obstruction is seen, no matter how small it may be, clean the bore with a cleaning rod and patch as described in the Cleaning and Maintenance section of this owner’s manual.

10 - BE ALERT TO THE SIGNS OF AMMUNITION MALFUNCTION. IF YOU DETECT AN OFF SOUND OR LIGHT RECOIL WHEN A CARTRIDGE IS FIRED, DO NOT LOAD ANOTHER CARTRIDGE INTO THE CHAMBER.

If your firearm fails to fire, keep the muzzle pointed in a safe direction for a minimum of 30 seconds. Rotate the ejection area of the firearm away from you, carefully open the action and remove the cartridge from the chamber. If the primer is indented, the defective cartridge should be disposed of in a way that cannot cause harm. If the primer is not indented, your firearm should be examined by a qualified gunsmith and the cause of the malfunction corrected before further use. Glance down the barrel to make sure that no obstructions remain in the barrel. Completely clear the barrel before loading and firing again. Failure to follow these instructions can cause extensive damage to your firearm and possible serious injury to yourself and others.

11 - NEVER INSERT A SHELL OF THE INCORRECT GAUGE INTO ANY FIREARM. The gauge of your firearm is marked on the barrel. Store all shells of different gauges in completely separate and well-marked containers. Never store shells of mixed gauges in a common container or in your pockets. See the Ammunition Section for more information on the correct ammunition for your firearm.

12 - EXAMINE EVERY SHELL YOU PUT IN YOUR FIREARM.

We assume no responsibility for the use of unsafe or improper firearm and ammunition combinations or damage or injury caused by damaged ammunition. It is your responsibility to read and heed all warnings in this owner’s manual and on ammunition boxes. See the Ammunition Section for more information on the correct ammunition for your firearm.

13 - USE ONLY SAAMI APPROVED AMMUNITION.

The barrel and action of this firearm have been made with substantial safety margins beyond the pressures developed by established American commercial loads. Nevertheless, we can assume no liability for incidents that occur through the use of cartridges of nonstandard dimensions or which develop pressures in excess of commercially available ammunition which have been loaded in accordance with standards established by the Sporting Arms and Ammunition Manufacturers’ Institute (SAAMI).

14 - DISCHARGING FIREARMS IN POORLY VENTILATED AREAS, CLEANING FIREARMS OR HANDLING AMMUNITION MAY RESULT IN EXPOSURE TO LEAD AND OTHER SUBSTANCES KNOWN TO CAUSE BIRTH DEFECTS, REPRODUCTIVE HARM AND OTHER SERIOUS PHYSICAL INJURY. HAVE ADEQUATE VENTILATION AT ALL TIMES. WASH HANDS THOROUGHLY AFTER EXPOSURE.

15 - DO NOT SNAP THE FIRING PIN ON AN EMPTY CHAMBER, THE CHAMBER MAY NOT BE EMPTY!

Treat every firearm with the respect due a loaded firearm, even though you are certain the firearm is unloaded.

16 - KEEP YOUR FINGERS AWAY FROM THE TRIGGER WHILE LOADING AND UNLOADING UNTIL SHOOTING IS IMMINENT.

17 - BE SURE OF YOUR TARGET AND BACKSTOP, PARTICULARLY DURING LOW LIGHT PERIODS. Know the range of your ammunition. Never shoot at water or hard objects.

18 - ALWAYS UNLOAD YOUR FIREARM'S CHAMBER BEFORE CROSSING A FENCE, CLIMBING A TREE, JUMPING A DITCH OR NEGOTIATING OTHER OBSTACLES. Never place your firearm on or against a fence, tree, car, or other similar object.

19 - BE DEFENSIVE AND ON GUARD AGAINST UNSAFE GUN HANDLING AROUND YOU AND OTHERS. Don’t be timid when it comes to firearm safety. If you observe other shooters violating any of these safety precautions, politely suggest safer handling practices.

20 - BE CERTAIN YOUR FIREARM IS UNLOADED BEFORE CLEANING. Special and extreme care should be taken to be sure your firearm is unloaded before disassembly, cleaning and reassembly.

Keep ammunition away from the cleaning location. Never test the mechanical function of any firearm with live ammunition.

21 - TEACH AND SUPERVISE FIREARMS SAFETY TO ALL MEMBERS OF YOUR FAMILY, ESPECIALLY TO CHILDREN AND NON-SHOOTERS. Closely supervise newcomers to the shooting sports. Encourage enrollment in hunting and shooting safety courses.

22 - NEVER DRINK ALCOHOLIC BEVERAGES OR TAKE ANY TYPE OF DRUGS BEFORE OR DURING SHOOTING. Your vision, motor skills, and judgment could be dangerously impaired, making your gun handling unsafe to you and to others.

23 - READ AND HEED ALL WARNINGS IN THIS OWNER'S MANUAL, ON AMMUNITION BOXES, AND WITH ALL ACCESSORIES THAT YOU INSTALL ON YOUR FIREARM. It is your responsibility to secure the most up-to-date information on the safe handling procedures of your Browning firearm. We assume no liability for incidents that occur when unsafe or improper firearm accessories or ammunition combinations are used.

24 - PRACTICE PERIODIC MAINTENANCE, AVOID UNAUTHORIZED SERVICING. Your firearm is a mechanical device that will not last forever, and as such, is subject to wear and requires periodic inspection, adjustment and service. Browning firearms should be serviced by a Browning Recommended Service Center or by our Service Facility in Arnold, Missouri. We cannot assume any responsibility for injuries suffered or caused by unauthorized servicing, alterations or modifications of Browning firearms.

25 - DO NOT, UNDER ANY CIRCUMSTANCES, ALTER THE TRIGGER, "SAFETY" OR OTHER PARTS OF THE FIRING MECHANISM OF THIS OR ANY OTHER FIREARM EXCEPT AS OTHERWISE DESCRIBED IN THIS MANUAL.

WE RESERVE THE RIGHT TO REFUSE SERVICE ON FIREARMS THAT HAVE BEEN ALTERED, ADDED TO OR SUBSTANTIALLY CHANGED. Removal of metal from the barrel, or modifications of the firing mechanism and/or operating parts, may lead to a refusal of service on such firearms. You will be charged for parts and labor to return the firearm to original specifications prior to servicing your firearm.

With respect to AFTERMARKET PARTS OR COMPONENTS (including, for example, aftermarket trigger systems, barrels, muzzle brakes, suppressors, magazines, etc.), USE AT YOUR OWN RISK. Browning firearms are designed and engineered to meet stringent safety standards. Browning is not responsible for personal injuries or property damage caused by alterations to a firearm. This includes the incorporation of aftermarket parts or components that may or may not satisfy Sporting Arms and Ammunition Manufacturers’ Institute (SAAMI) standards (for example, an aftermarket trigger system may not satisfy SAAMI minimum trigger pull standards, etc.) or may create other dangerous conditions. These conditions may or may not be apparent to the user (for example, installing an aftermarket barrel may have the effect of altering critical firearm dimensions, including headspace, and may create an unsafe firing condition, etc.). Aftermarket parts or components that do not satisfy SAAMI standards, or that could create other dangerous conditions, should not be used.

FAILURE TO FOLLOW THIS WARNING COULD RESULT IN SERIOUS INJURY OR DEATH, AS WELL AS CAUSE DAMAGE TO YOUR FIREARM.

BE CAREFUL!

BE CAREFUL!

GENERAL DESCRIPTION AND OPERATION

The Browning BPS is a manually operated, slide action, repeating shotgun. The action mechanism is operated by moving the slide (forearm) in a rearward motion, followed by a forward motion. This action unlocks the breech block, extracts and ejects the fired hull, transfers a live shell from the magazine to the chamber and locks the breech block. The BPS is loaded from the bottom of the receiver and fired hulls are ejected from a bottom ejection port. Bottom loading and ejection makes the BPS ambidextrous. The BPS is designed so the barrel can be easily removed by unscrewing the magazine cap from the magazine tube and then sliding the barrel forward out of the receiver. This facilitates easy cleaning, transportation and storage.

NOMENCLATURE

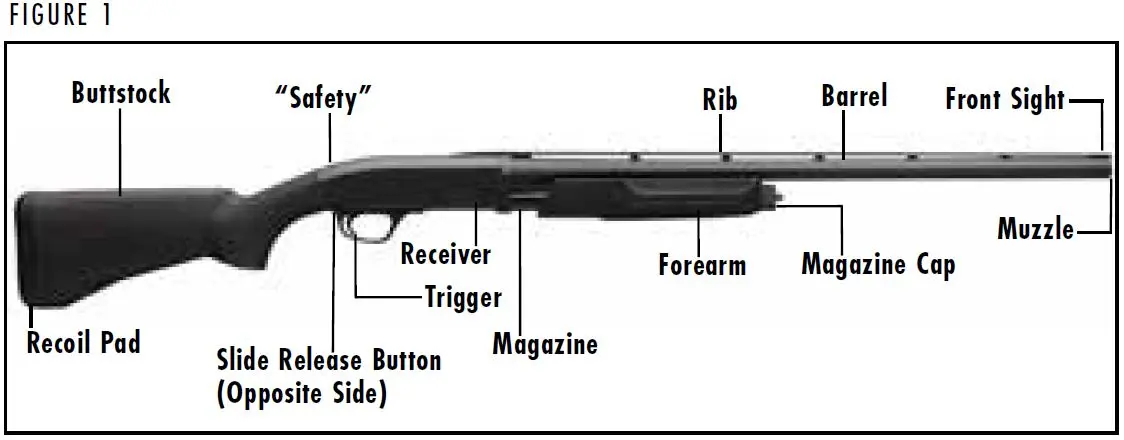

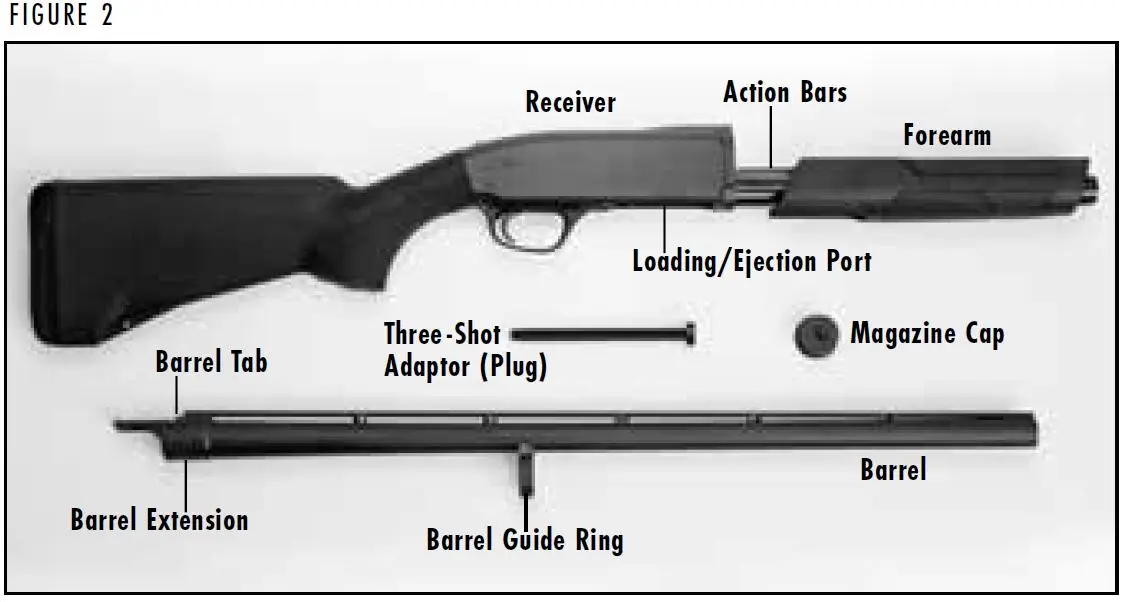

In conventional firearm terminology the position and movement of firearm parts are described as they occur with the firearm horizontal and in the normal firing position: i.e., the muzzle is forward or in front; the buttstock is rearward or to the rear; the trigger is downward or underneath; the rib is upward or on top. For general parts nomenclature, refer to Figure 1. For specific parts names related to disassembly, refer to Figure 2.

SERIAL NUMBER

The serial number of your BPS shotgun is found on the right side of the receiver, at the bottom, near the front, just above the loading/ejection loading port.

Initial Cleaning

Initial Cleaning

CLEANING PARTS WITH SPECIAL FINISHES

Various exposed metal parts of your new firearm have been coated at the factory with a rust preventative compound. Before assembling your shotgun, clean the anti-rust compound from the inside of the barrel, receiver and the action/chamber areas. A high-quality lightweight gun oil is ideal for removing this compound, and for giving your new firearm its first lubrication. Clean the barrel using a cleaning rod and patch as explained under the “Cleaning and Maintenance Suggestions” section.

CLEANING

Various exposed metal parts of your new firearm have been coated at the factory with a rust preventative compound. Before assembling your shotgun, clean the anti-rust compound from the inside of the barrel, receiver and the action/chamber areas. A high-quality lightweight gun oil is ideal for removing this compound, and for giving your new firearm its first lubrication. Clean the barrel using a cleaning rod and patch as explained under the “Cleaning and Maintenance Suggestions” section below.

WARNING: ALWAYS KEEP THE “SAFETY” IN THE ON SAFE POSITION UNLESS SHOOTING IS IMMINENT. ALWAYS KEEP THE MUZZLE POINTED IN A SAFE DIRECTION. FAILURE TO FOLLOW THESE WARNINGS COULD RESULT IN SERIOUS INJURY OR DEATH.

Operation of the "Safety"

Operation of the "Safety"

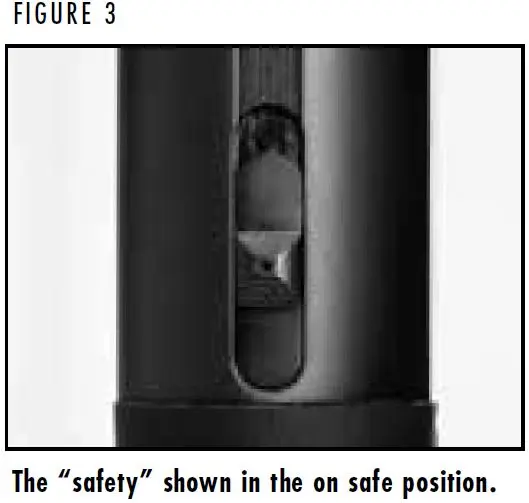

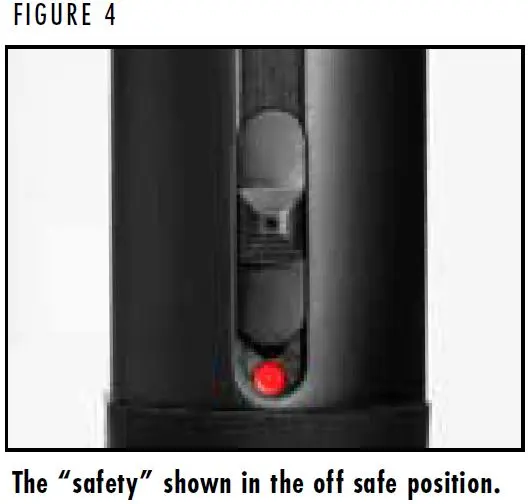

The “safety” is located on the top rear portion of the receiver. To move the “safety” to the on safe position, slide the “safety” rearward with your thumb so that the red warning dot is covered (Figure 3).

To move the “safety” to the off safe position, slide the “safety” forward with your thumb, exposing the red warning dot, indicating that the firearm is ready to fire (Figure 4).

WARNING: DO NOT DEPEND ON THE RED COLOR ALONE TO INDICATE YOUR FIREARM’S SAFETY STATUS. TIME, EXPOSURE TO THE ELEMENTS, AND THE ABRASIVE ACTION OF CLEANING AGENTS CAN ERASE IT. FAILURE TO FOLLOW THIS WARNING COULD RESULT IN SERIOUS INJURY OR DEATH.

Slide Release Button

Slide Release Button

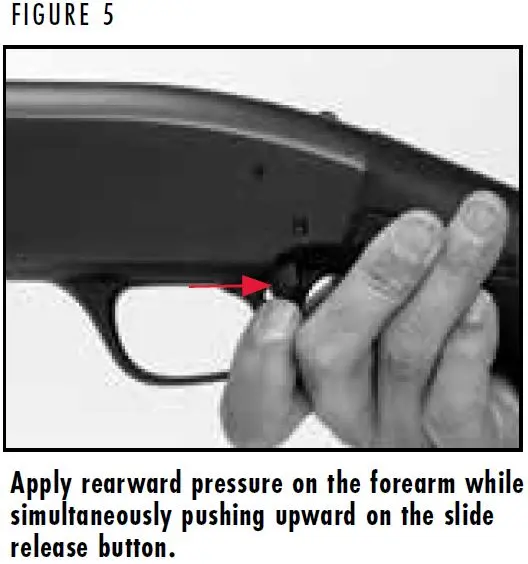

When the forearm on the BPS is positioned fully forward it locks into position, closing and locking the breech block. It is necessary to release the breech block and allow the forearm to be pulled rearward, in order to follow the “Assembly” section and normal firing procedures. The button is located on the left side of the trigger guard, at the rear, behind the trigger (Figure 5).

To release the slide, apply rearward pressure on the forearm while simultaneously pushing up on the slide release button. The button moves upward and slightly to the rear when depressed.

If you are a right-handed shooter, reach under the rear of the trigger guard, to the opposite side with your finger and push up on the button. Left-handed shooters simply lift up on the button with your trigger finger. Specific uses of the slide release button are outlined in the following sections.

WARNING: ALWAYS KEEP THE MUZZLE POINTED IN A SAFE DIRECTION. BEFORE STARTING ASSEMBLY PROCEDURES, VISUALLY INSPECT THE CHAMBER TO BE ABSOLUTELY CERTAIN THE FIREARM IS COMPLETELY UNLOADED. PLACE THE “SAFETY” IN THE ON SAFE POSITION. FAILURE TO FOLLOW THIS WARNING COULD RESULT IN SERIOUS INJURY OR DEATH.

Assembly

Assembly

The BPS is delivered, in the box, with the barrel removed and the forearm still attached to the magazine tube.

NOTICE: IT IS IMPORTANT TO FOLLOW THE EXACT SEQUENCE FOR ASSEMBLY IN STEPS 1 AND 2, IN ORDER TO PROPERLY ASSEMBLE YOUR BPS.

1. Remove the magazine cap. Depress the slide release button and pull the forearm completely rearward.

IMPORTANT: In order to introduce the barrel extension into the receiver, the carrier must be lowered. To lower the carrier, the forearm must be moved completely to the rear. Then, the forearm must be partially moved forward (step 2) so that the barrel extension will not bind against the carrier. With the ejection port downward, the bolt will retain the carrier in a position low enough to allow easy insertion of the barrel.

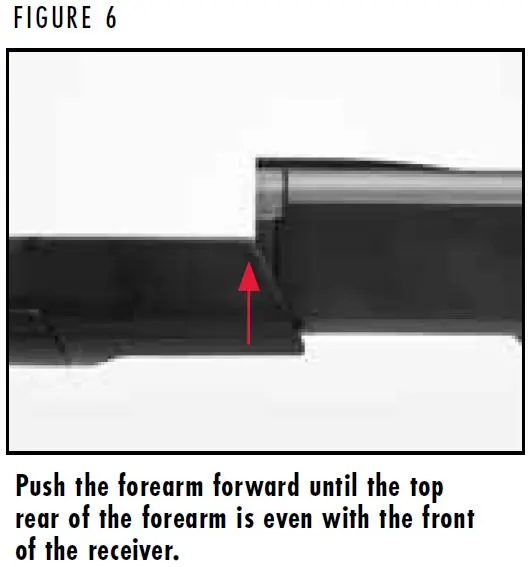

2. Hold the stock/receiver in a horizontal position with the ejection port down. Then, with the forearm already in the fully rearward position, push the forearm forward until the rear of the forearm is even with the front of the receiver (Figure 6).

NOTICE: DO NOT SQUEEZE HARD ON THE OPEN REAR END OF A WOOD FOREARM. TOO MUCH PRESSURE COULD CAUSE THE WOOD TO SPLIT.

3. Before attaching the barrel, be sure to glance through the bore to be sure it is clear of any obstructions.

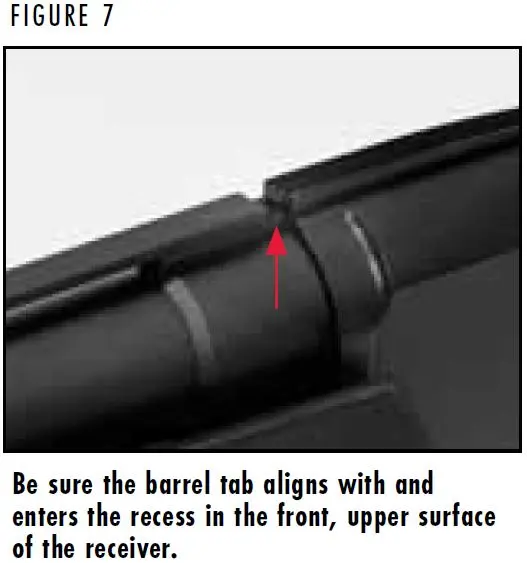

4. With the forearm positioned as explained in step 2, insert the barrel extension into the receiver. Move the barrel rearward, guiding the barrel guide ring over the magazine tube. The barrel tab projects from the most rearward rib post on the top of the barrel. Be sure the barrel tab aligns with and enters the recess in the front, upper surface of the receiver (Figure 7).

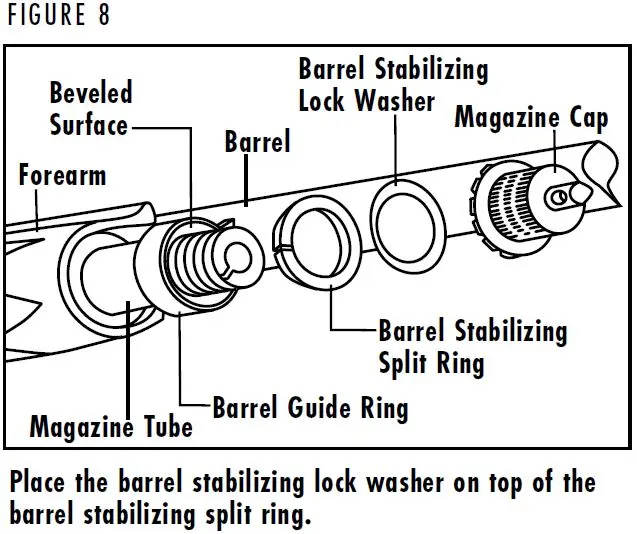

IMPORTANT: BPS Deer guns are shipped with a barrel stabilizing split ring and a barrel stabilizing lock washer on the magazine tube. This special design ensures a very rigid barrel mounting method for maximum accuracy. You must remove the barrel stabilizing ring and washer from the magazine tube before installing the barrel. After mounting the barrel to the action, slide the barrel stabilizing split ring on the magazine tube, being sure that the beveled surfaces of both the split ring and the guide ring match. Place the lock washer on top of the split ring (Figure 8).

5. Replace the magazine cap.

WARNING: ALWAYS KEEP THE MUZZLE POINTED IN A SAFE DIRECTION. BEFORE STARTING DISASSEMBLY PROCEDURES, OPEN THE ACTION AND VISUALLY INSPECT THE CHAMBER TO BE ABSOLUTELY CERTAIN THE FIREARM IS COMPLETELY UNLOADED. PLACE THE “SAFETY” IN THE ON SAFE POSITION. FAILURE TO FOLLOW THIS WARNING COULD RESULT IN SERIOUS INJURY OR DEATH.

Disassembly

Disassembly

- Place the slide in its forward position. Unscrew the magazine cap and remove it.

- Holding the receiver in one hand, and the barrel in the other, ease the barrel forward off the magazine tube and out of the receiver. IMPORTANT: On BPS Deer models it is necessary to first remove the barrel stabilizing lock washer and split ring before removing the barrel (Figure 8).

- No further disassembly is recommended.

WARNING: DISCHARGING FIREARMS IN POORLY VENTILATED AREAS, CLEANING FIREARMS OR HANDLING AMMUNITION MAY RESULT IN EXPOSURE TO LEAD AND OTHER SUBSTANCES KNOWN TO CAUSE BIRTH DEFECTS, REPRODUCTIVE HARM AND OTHER SERIOUS PHYSICAL INJURY. HAVE ADEQUATE VENTILATION AT ALL TIMES. WASH HANDS THOROUGHLY AFTER EXPOSURE.

USE ONLY SHELLS OF THE CORRECT GAUGE AND LENGTH. THE GAUGE AND LENGTH OF THE CHAMBER IS INSCRIBED ON THE SIDE OF THE BARREL. DO NOT USE AMMUNITION OTHER THAN WHAT IS INSCRIBED ON THE SIDE OF THE BARREL. EXAMINE EVERY SHELL YOU PUT IN YOUR SHOTGUN. FAILURE TO FOLLOW THIS WARNING COULD RESULT IN SERIOUS INJURY OR DEATH AND CAUSE DAMAGE TO YOUR SHOTGUN.

USE SHELLS OF THE CORRECT LENGTH. DO NOT USE 3" OR 3½" SHELLS IN A BARREL WITH A 2¾" OR 2½" CHAMBER, OR 3½" SHELLS IN A BARREL WITH A 3" CHAMBER. DOING SO CAN RESULT IN A BUILDUP OF DANGEROUSLY HIGH PRESSURES. FAILURE TO FOLLOW THIS WARNING COULD RESULT IN SERIOUS INJURY OR DEATH AND CAUSE DAMAGE TO YOUR SHOTGUN.

DO NOT PUT A 16 OR 20 GAUGE SHELL IN A 12 GAUGE SHOTGUN. DO NOT PUT A 28 GAUGE SHELL IN A 20 GAUGE SHOTGUN. DO NOT PUT A .410 BORE SHELL IN A 28 GAUGE SHOTGUN. NEVER PUT METALLIC CARTRIDGES OF ANY KIND IN A SHOTGUN. SPECIFICALLY, NEVER PUT CENTERFIRE RIFLE OR PISTOL CARTRIDGES IN A SHOTGUN CHAMBERED FOR .410 BORE. FAILURE TO FOLLOW THIS WARNING COULD RESULT IN SERIOUS INJURY OR DEATH AND CAUSE DAMAGE TO YOUR SHOTGUN.

Ammunition

Ammunition

The most certain way to bulge or rupture a shotgun barrel is to load a smaller gauge shell into a larger gauge chamber. The smaller gauge shell will not fall completely through the barrel; its rim is caught by the front of a larger gauge chamber or at the larger gauge’s choke. Your shotgun will misfire (with the chamber appearing to be empty).

It is then possible to load the correct gauge shell behind the smaller gauge shell. If the shotgun is then fired, the result will be a so-called “12-16, 12-20, 20-28 or 28-.410 burst” which can cause extensive damage to your shotgun and possible serious injury to you and others.

The barrel and action of this firearm have been made with safety margins over the pressures established by the Sporting Arms and Ammunition Manufacturers’ Institute (SAAMI) for Service Cartridges. However, we assume no responsibility for incidents which occur through the use of cartridges of nonstandard dimension or those developing pressures in excess of SAAMI established standards.

BPS 3" chamber models will shoot all factory lead and steel 2¾" and 3" field loads. BPS 3½" chamber models will shoot all factory lead and steel 12 gauge 2¾", 3" and 3½" field loads.

Magazine Capacity

Magazine Capacity

With the magazine three-shot adaptor (plug) removed, BPS 3" shotguns will hold four 2¾" or three 3" shells in the magazine. BPS 3½" shotguns will hold four 2¾", or three 3" or 3½" shells in the magazine.

WARNING: ALWAYS KEEP THE MUZZLE POINTED IN A SAFE DIRECTION. BEFORE REMOVING OR INSTALLING THE THREE-SHOT ADAPTOR, COMPLETELY UNLOAD THE SHOTGUN. OPEN THE ACTION AND VISUALLY INSPECT THE CHAMBER, FEED MECHANISM AND MAGAZINE TO BE ABSOLUTELY CERTAIN THE FIREARM IS COMPLETELY UNLOADED. PLACE THE “SAFETY” IN THE ON SAFE POSITION. FAILURE TO FOLLOW THIS WARNING COULD RESULT IN SERIOUS INJURY OR DEATH.

WEAR EYE PROTECTION WHEN REMOVING OR INSTALLING THE THREE-SHOT ADAPTOR TO PREVENT SPRINGS, SPRING-LOADED PARTS, SOLVENTS OR OTHER AGENTS FROM CONTACTING YOUR EYES, RESULTING IN INJURY.

Three-Shot Adaptor (Plug)

Three-Shot Adaptor (Plug)

The BPS shotgun is delivered with the magazine three-shot adaptor (plug) installed in the magazine, limiting magazine capacity to two shells in compliance with federal migratory bird regulations. If you do not wish to be limited to three shots, when it is not required by law, you can remove (or reinstall) the three-shot adaptor as follows:

REMOVING THE THREE-SHOT ADAPTOR (PLUG)

1. Unscrew the magazine cap and remove it.

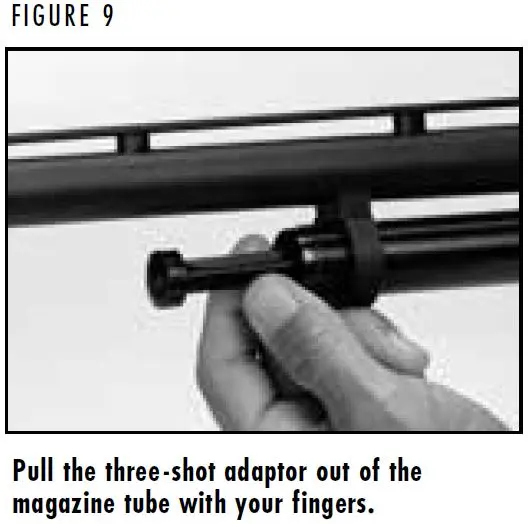

2. The magazine three-shot adaptor lays on top of the magazine spring retainer located in the forward end of the magazine tube and is only held in the magazine tube by the magazine cap. Simply pull the three-shot adaptor out of the magazine tube with your fingers to remove (Figure 9). (You may also hold the shotgun muzzle down to let it slide out.).

3. Reinstall the magazine cap.

INSTALLING THE THREE-SHOT ADAPTOR (PLUG)

If you need to install the magazine three-shot adaptor (plug) to limit the magazine to two shells, perform the following operation:

1. Unscrew the magazine cap and remove it.

2. Insert the three-shot adaptor (plug) into the magazine until

it is level with the end of the magazine tube.

3. Reinstall the magazine cap.

WARNING: WHEN LOADING YOUR SHOTGUN ALWAYS KEEP THE MUZZLE POINTED IN A SAFE DIRECTION, ALWAYS PLACE THE “SAFETY” IN THE ON SAFE POSITION AND KEEP YOUR FINGERS AWAY FROM THE TRIGGER. FAILURE TO FOLLOW THESE WARNINGS COULD RESULT IN SERIOUS INJURY OR DEATH.

DO NOT CARRY YOUR SHOTGUN WITH A SHELL IN THE CHAMBER TO AVOID ACCIDENTAL DISCHARGE. WHEN FIRING IS NO LONGER IMMINENT, MAKE SURE THE “SAFETY” IS IN THE ON SAFE POSITION AND UNLOAD THE CHAMBER. FAILURE TO FOLLOW THESE WARNINGS COULD RESULT IN SERIOUS INJURY OR DEATH.

Loading

Loading

LOADING THE MAGAZINE

- Press the slide release button and pull the forearm completely rearward. With the bolt in the open position visually inspect the chamber, feed mechanism and magazine to make sure they are unloaded and clear of any obstructions.

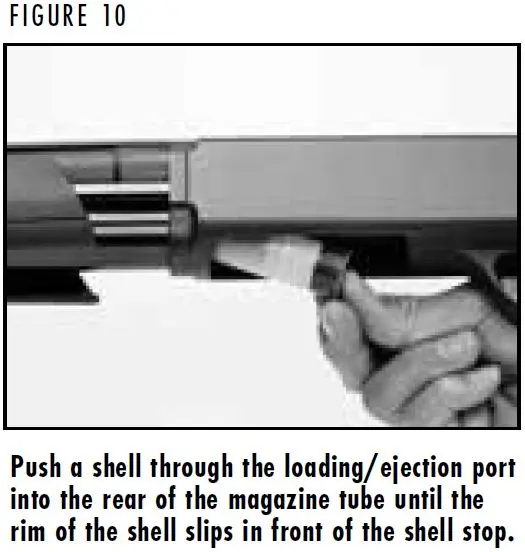

- Close the bolt by pushing the forearm completely forward.

- Insert a shell of the proper gauge and length through the loading port at the bottom of the receiver. Push it forward into the magazine, using your thumb to position it fully forward in the magazine tube (Figure 10). Make certain the rim of the shell engages the shell stop and is held fully inside the magazine tube. It will make an audible click when fully inserted.

- Continue loading the magazine until it is full.

LOADING THE CHAMBER MANUALLY FROM THE MAGAZINE

1. Load the magazine as explained previously.

2. If firing is imminent, a shell can be moved from the magazine to the chamber by pressing the slide release button and completely cycling the action. A shell will be fed from the magazine to the chamber as the bolt closes.

WARNING: THE SHOTGUN IS NOW READY TO FIRE BY SIMPLY MOVING THE “SAFETY” TO THE OFF SAFE POSITION AND PULLING THE TRIGGER.

3. Another shell can then be inserted into the magazine to load to full capacity.

WARNING: NEVER LOAD A SHELL INTO THE CHAMBER OR PLACE THE “SAFETY” IN THE OFF SAFE POSITION UNLESS SHOOTING IS IMMINENT. ALWAYS KEEP THE MUZZLE POINTED IN A SAFE DIRECTION. FAILURE TO FOLLOW THESE WARNINGS COULD RESULT IN SERIOUS INJURY OR DEATH.

Firing

Firing

- Load a shell into the chamber as explained previously and immediately place the “safety” in the on safe position.

- With a shell in the chamber, you need only move the “safety” to the off safe position to fire the shotgun.

- When ready to fire, move the “safety” into the off safe position, take aim and pull the trigger.

After a shell is fired, you may continue to fire the shotgun until the magazine is empty by cycling the action with the forearm to eject the empty hull, load a new shell from the magazine and pulling the trigger.

You can then reload the magazine or, if you are done shooting, pull the forearm completely rearward and visually inspect the chamber, bore, carrier and magazine to be sure they contain no shells.

WARNING: AFTER FIRING, OR WHEN SHOOTING IS NO LONGER IMMINENT, IMMEDIATELY PLACE THE “SAFETY” IN THE ON SAFE POSITION. FAILURE TO FOLLOW THESE WARNINGS COULD RESULT IN SERIOUS INJURY OR DEATH.

EVEN WITH THE BOLT LOCKED OPEN AFTER SHOOTING, DO NOT ASSUME THE SHOTGUN IS UNLOADED. ALWAYS INSPECT THE CHAMBER, BARREL, FEED MECHANISM AND MAGAZINE TO BE CERTAIN THE SHOTGUN IS COMPLETELY UNLOADED. FAILURE TO FOLLOW THESE WARNINGS COULD RESULT IN SERIOUS INJURY OR DEATH.

WARNING: WHEN UNLOADING YOUR SHOTGUN ALWAYS PLACE THE “SAFETY” IN THE ON SAFE POSITION. KEEP THE MUZZLE POINTED IN A SAFE DIRECTION AND YOUR FINGERS AWAY FROM THE TRIGGER. FAILURE TO FOLLOW THESE WARNINGS COULD RESULT IN SERIOUS INJURY OR DEATH.

ALWAYS INSPECT THE CHAMBER, BARREL, FEED MECHANISM AND MAGAZINE CAREFULLY AFTER UNLOADING TO BE SURE ALL LIVE SHELLS ARE CLEARED FROM THE FIREARM.

Unloading

Unloading

- Place the forearm in the completely forward position.

- Turn the shotgun over so the trigger guard is facing up, then push the carrier down with your finger as far as it will go.

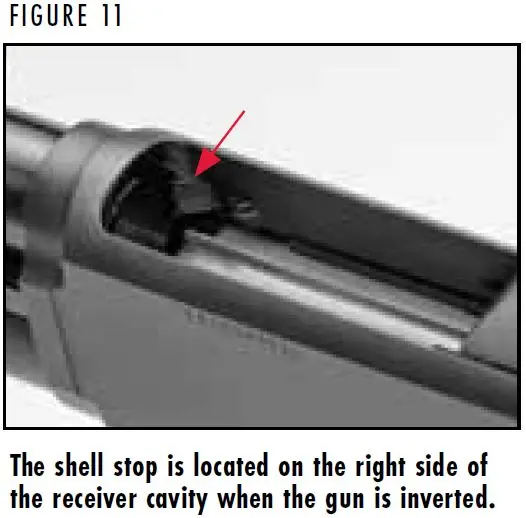

- Locate the shell stop inside the receiver on the left side of the loading port (visually to your right side when looking down into the loading port). Shells in the magazine are retained in the magazine by the shell stop, which catches on the rim of the shell base.

- Push inward on the shell stop with your index finger (Figure 11) to release a shell from the magazine. As the shell stop is pressed in, the shell will be forced out of the magazine under spring pressure. Capture the shell as it comes out. Be careful not to pinch your finger.

- Press the stop again to release the next shell. Continue to do this until the magazine is empty.

- With the “safety” in the on safe position, press the slide release button and slowly pull the forearm completely rearward to eject the shell from the chamber. With the chamber empty, slide the forearm completely forward.

- Using your index finger, feel the entry of the magazine to make sure there are no shells that have not been fed from the magazine and ejected. Visually inspect the chamber, feed mechanism and magazine to assure there are no shells remaining.

WARNING: NEVER ATTEMPT TO REMOVE OR INSTALL A CHOKE TUBE IN A LOADED FIREARM. WHENEVER REMOVING OR INSTALLING A CHOKE TUBE IN A SHOTGUN ALWAYS KEEP THE MUZZLE POINTED IN A SAFE DIRECTION. OPEN THE ACTION AND MAKE ABSOLUTELY CERTAIN THE SHOTGUN IS COMPLETELY UNLOADED, ALWAYS PLACE THE “SAFETY” IN THE ON SAFE POSITION AND KEEP YOUR FINGERS AWAY FROM THE TRIGGER. FAILURE TO FOLLOW THESE WARNINGS COULD RESULT IN SERIOUS INJURY OR DEATH.

CAUTION: BROWNING INVECTOR-DS, INVECTOR-PLUS AND STANDARD INVECTOR CHOKE TUBES ARE NOT INTERCHANGEABLE. DO NOT USE BROWNING INVECTOR-PLUS, STANDARD INVECTOR OR INVECTOR-DS CHOKE TUBES IN ANY SHOTGUN BARREL NOT SUPPLIED BY BROWNING. DO NOT USE ANY OTHER CHOKING DEVICE IN ANY SHOTGUN BARREL SUPPLIED BY BROWNING.

USE ONLY THE APPROPRIATE GAUGE OF INVECTOR CHOKE TUBE IN THIS SHOTGUN. DO NOT FIRE THIS SHOTGUN WITHOUT THE CORRECT CHOKE TUBE INSTALLED. DAMAGE MAY RESULT TO THE THREADS INSIDE THE BARREL.

FAILURE TO FOLLOW THIS INFORMATION COULD RESULT IN DAMAGE TO YOUR SHOTGUN OR POSSIBLE INJURY.

NOTICE: USE ONLY THE INVECTOR CHOKE TUBE WRENCH SUPPLIED WITH YOUR SHOTGUN TO INSTALL AND REMOVE INVECTOR CHOKE TUBES. USING ANY OTHER WRENCH MAY DAMAGE THE THREADS IN THE BARREL.

Interchangeable Choke Tube System

Interchangeable Choke Tube System

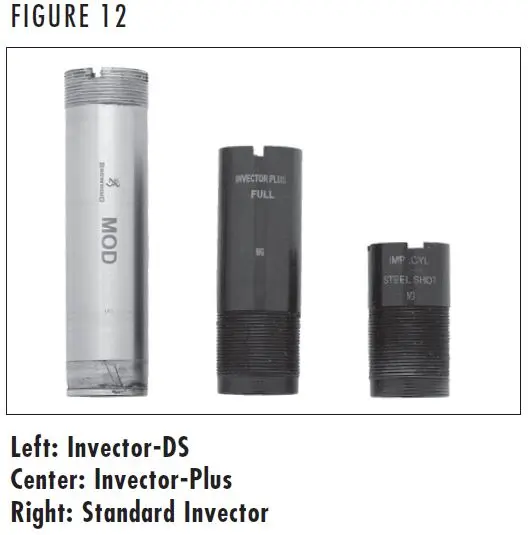

Pre-1983 BPS models are conventionally choked. Current BPS shotguns have barrels that are threaded to accept either the Standard Invector™ or Invector-Plus™ choke tube systems. Browning Standard Invector, Invector-Plus and Invector-DS tubes are not interchangeable. Confirm the choke system of your shotgun by looking on the right side of the barrel where the specifications are inscribed, Invector choke tubes are identified in Figure 12 (flush mount tubes are shown).

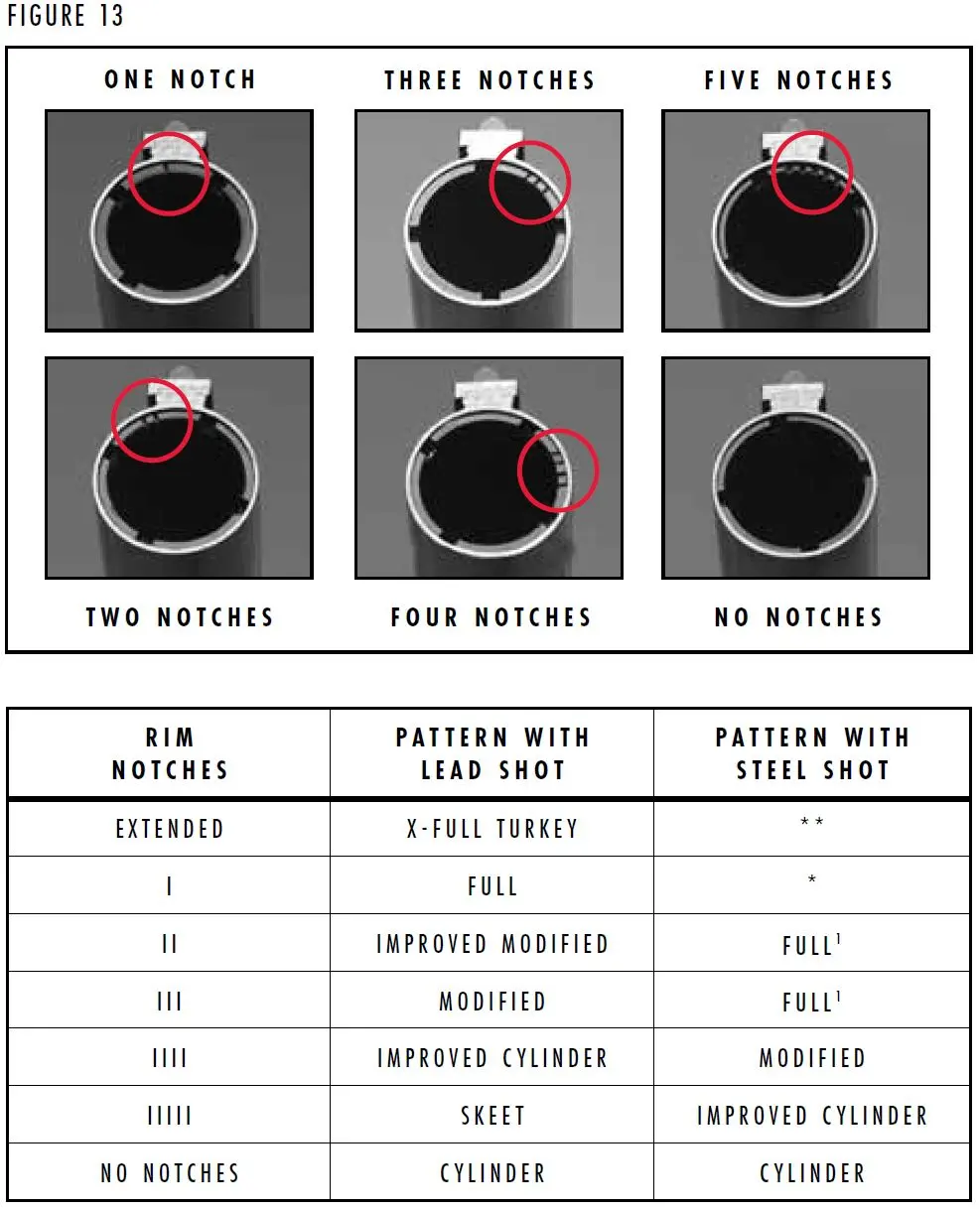

The constriction of each choke tube is indicated twice on the choke tube: On the side of the tube, and indicated with a “notch” code on the top rim of the tube. The included choke tube T-Wrench is used to remove and install choke tubes.

Some target shotguns include premium extended choke tubes. The constriction of premium choke tubes is indicated twice on the choke tube: On the side of the tube, and indicated with an abbreviation in the colored band. The constriction of flush fit choke tubes is indicated twice on the choke tube: On the side of the tube, and indicated with a “notch” code on the top rim of the tube. The included choke tube T-Wrench is used to remove and install extended choke tubes.

Invector choke tubes are compatible with factory ammunition that has been loaded in compliance with SAAMI specifications, including magnum lead and steel shot loads, sabots and slug loads.

Replacement and additional tubes and wrenches are available from your Browning dealer, or by contacting our Consumer Department. See the “Service or Repair”section for contact information.

CHOKE TUBE SELECTION

To help you choose the correct choke tube for each hunting and shooting situation, all Browning Invector choke tubes are inscribed on the side with the patterns they produce with both lead and steel shot. Each Invector tube also has notches in the top rim of the tube (Figure 13). These notches are a code to allow you to determine the choke designation while the tube is installed. Rim notches refer specifically to lead shot. You will need to use the chart on page 25 to cross-reference from lead to steel, and determine the appropriate tubes for your ammunition and hunting/shooting situation.

Several choke tubes are supplied with your shotgun. The choke tubes listed are also available as accessories. Remember that Invector-DS, Invector-Plus and Standard Invector tubes are not interchangeable. Before removing or installing tubes, or reading the rim notch code, make sure your shotgun is completely unloaded and the “safety” is in the on safe position.

CHOKE TUBE REMOVAL

- Place the “safety” in the on safe position. Always make sure the shotgun is completely unloaded. Always keep the muzzle pointed in a safe direction.

- Use the choke tube wrench to loosen the tube, turning it counterclockwise. Finger-twist the tube the rest of the way out of the barrel.

CHOKE TUBE INSTALLATION

- Place the “safety” in the on safe position. Always make sure the shotgun is completely unloaded. Always keep the muzzle pointed in a safe direction.

- Before installing a tube, check the internal choke tube threads in the muzzle, as well as the threads on the choke tube to be sure they are clean. Lightly oil the threads with a high-quality, lightweight gun oil.

- Using your fingers, screw the appropriate tube into the muzzle of the barrel, tapered end first, notched end outward. When it becomes finger-tight, use the choke tube wrench to firmly seat the tube.

NOTICE: FAILURE TO CLEAN AND OIL THE THREADS ON THE CHOKE TUBE COULD RESULT IN THE CHOKE TUBE SEIZING IN THE BARREL.

* Not for use with steel shot. Using an over-tight choke constriction with steel shot will result in an ineffective “blown” pattern.

** Extra Full Special, extended tube with ports. Do not use with steel shot.

1 When more than one choke designation is listed for a given steel shot pattern, use the more open choke listed for high velocity, larger shot size steel loads.

NOTICE: THE CHOKE TUBE SHOULD BE PERIODICALLY CHECKED TO ASSURE THAT IT IS TIGHT AND FIRMLY SEATED. BEFORE CHECKING, FOLLOW ALL CHOKE TUBE REMOVAL AND INSTALLATION SAFETY GUIDELINES PREVIOUSLY OUTLINED.

Length of Pull Adjustment

Length of Pull Adjustment

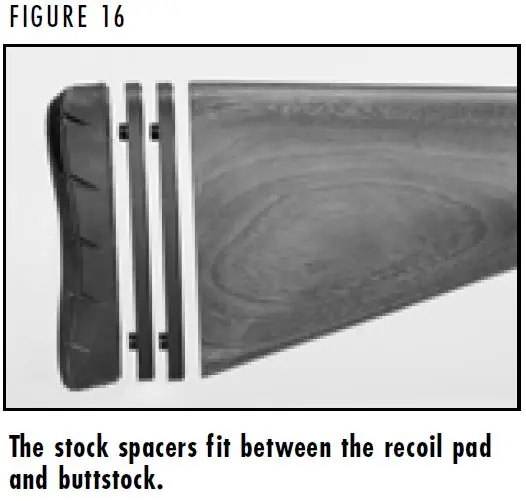

The stock of BPS shotguns with the Inflex recoil pad can be adjusted for length of pull by adding or removing spacers to the rear of the stock. Each spacer changes length of pull ¼". One spacer can be added using the screws provided. Micro and Micro Midas models include a set of longer screws, allowing a maximum of three ¼" spacers to be added to extend length of pull up to ¾".

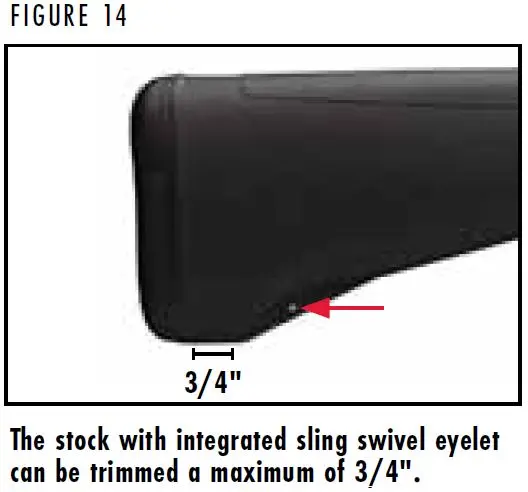

We recommend contacting a professional gunsmith if a shorter length of pull is required. Wood stock models require cutting the stock and replacing and fitting a new recoil pad. Composite stock models that include the integrated sling swivel eyelet (Figure 14) can be trimmed a maximum of ¾" and the Inflex recoil pad reinstalled using shorter screws (not provided). The length of the screws will be determined by the amount of material removed from the stock. Composite stocks without the integrated eyelet shown in Figure 14 cannot be shortened.

If longer or shorter screws are required, commonly found No. 7 panhead, Phillips, self-tapping wood screws of the necessary length are the recommended replacement screws. Spacers can be ordered through your Browning dealer or by calling our Customer Service Department at (800) 322-4626.

WARNING: BEFORE PERFORMING ADJUSTMENT PROCEDURES, PLACE THE “SAFETY” IN THE ON SAFE POSITION. OPEN THE ACTION AND MAKE CERTAIN YOUR SHOTGUN IS COMPLETELY UNLOADED. KEEP THE MUZZLE POINTED IN A SAFE DIRECTION. FAILURE TO FOLLOW THESE WARNINGS COULD RESULT IN SERIOUS INJURY OR DEATH.

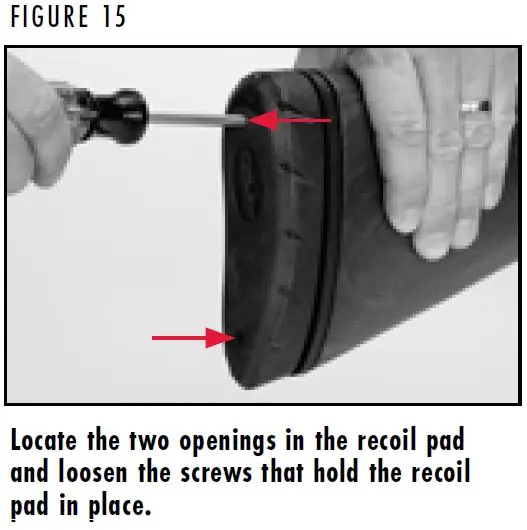

ADJUSTING LENGTH OF PULL USING SPACERS

- Use a #2 cross tip or Phillips screwdriver to remove the recoil pad (Figure 15). Place a small amount of petroleum jelly on the screw access slits on the top and bottom of the rear of the buttstock to prevent damaging the recoil pad. Insert the screwdriver into each of the two access holes. Make certain the tip of the screwdriver engages the head of the screw. Turn the screw counterclockwise until the screw is completely loose from the stock. When both screws are free, remove the recoil pad.

- Add or subtract spacers to fit your firearm to your specifications (Figure 16). After making an adjustment hold the shotgun to your shoulder to determine if the new length feels comfortable. Remember to always keep the muzzle pointed in a safe direction, with the “safety” in the on safe position and make certain the shotgun is completely unloaded.

- When you are satisfied with the length of pull, start the screws through the recoil pad and spacer(s) into the holes in the stock.

- Attach the recoil pad to the stock using the screwdriver. Turn the screws clockwise to tighten. Do not overtighten the screws.

WARNING: BEFORE INSTALLING ACCESSORY BARRELS ON YOUR SHOTGUN, READ THE FOLLOWING GUIDELINES TO ENSURE THE BARREL/SHOTGUN COMBINATION IS SAFE. PLACE THE “SAFETY” IN THE ON SAFE POSITION. OPEN THE ACTION AND MAKE CERTAIN YOUR SHOTGUN IS COMPLETELY UNLOADED. KEEP THE MUZZLE POINTED IN A SAFE DIRECTION. FAILURE TO FOLLOW THESE WARNINGS COULD RESULT IN SERIOUS INJURY OR DEATH.

Extra Barrels

Extra Barrels

The versatility of your BPS can be extended with an extra barrel. BPS barrels are interchangeable within gauge and chamber length. No special fitting is required. However, some important restrictions must be observed:

- Never use a barrel with a 3½" chamber on a shotgun designed for barrels with a 3" chamber.

- Never use a barrel with a 3" chamber on a shotgun designed for barrels with a 3½" chamber.

- Never use any other barrel from any other manufacturer on your shotgun. Some other brands may seem similar, but the barrels are not interchangeable.

- Never use a barrel from any other Browning shotgun.

WARNING: BEFORE MOUNTING A SCOPE, SIGHT OR OTHER ACCESSORIES TO YOUR SHOTGUN, PLACE THE “SAFETY” IN THE ON SAFE POSITION. OPEN THE ACTION AND MAKE CERTAIN YOUR SHOTGUN IS COMPLETELY UNLOADED. KEEP THE MUZZLE POINTED IN A SAFE DIRECTION. FAILURE TO FOLLOW THESE WARNINGS COULD RESULT IN SERIOUS INJURY OR DEATH.

Installing A Scope or Optics

Installing A Scope or Optics

Some BPS shotguns are designed to accept a scope or other optical sight; usually these are turkey and deer models. The receivers of some of these models are drilled and tapped for scope bases, while other models are equipped with a cantilever scope base. If your shotgun has a cantilever mount, follow the mounting instructions supplied with your scope rings and/or scope. If your shotgun’s receiver is drilled and tapped for scope mounts, three holes (in line on top of the receiver) will be visible. They are fitted with filler screws. If your shotgun is drilled and tapped, adhere to the following:

NOTICE: YOUR SHOTGUN IS DRILLED AND TAPPED FOR THE MOUNTING OF BASES AND RINGS TO ACCOMMODATE AN APPROPRIATE SCOPE OR SIGHT. ALWAYS USE THE CORRECT BASES FOR THIS SHOTGUN WITH THE APPROPRIATE LENGTH SCREWS WHICH ARE AT LEAST 11/32" IN LENGTH.

- Place your shotgun on a table or other safe/secure location. Protect the finish with rags or other padding.

- You should have a compatible one-piece style base and three screws of at least 11/32" in length.

- Clean all oil, grease or dirt from the receiver top and from the scope base parts.

- Position your shotgun in the horizontal position with the top of the receiver upward.

- Remove all three filler screws from the top of the receiver using a very small, thin-bladed gunsmithing-type screwdriver.

- Pre-position the base on the receiver top to determine the best orientation of the base. Most bases have transverse grooves cut into them that are offset from the middle. These are the grooves that the crossbolts in your scope rings will pass through. The grooves are offset to allow you to position the bases to fit the design/length of your scope and the placement of the scope, front to rear for proper eye relief. Place both grooves to the rear, both to the front, or one in each direction, depending on the desired position of your scope.

- Once you know which configuration you will use, insert the screws through the base and screw it into the receiver top using the correct wrench or screwdriver (usually a 3/32" hex wrench). You must use screws that are at least 11/32" in length to ensure proper thread engagement. Once the bases are installed, check inside the receiver to verify that the base mounting screws are not too long and interfering with the operation of the bolt. Many gunsmiths find it helpful to use a drop of serviceable blue thread locking compound to assure the screws stay tight. Make sure the thread locking compound does not get into the action. Be careful to assure that the threads of each screw engage properly in the threads in the receiver to prevent stripping the threads in the receiver.

- Tighten the screws snugly, but do not overtighten.

- Mount your scope rings and scope as outlined in the instructions supplied with your scope rings and/or scope. Always make sure you have the proper eye relief. Always make sure that the saddle crossbolts and cap bolts are fully tightened before using your shotgun.

WARNING: BEFORE MAKING SIGHT ADJUSTMENTS TO YOUR SHOTGUN, PLACE THE “SAFETY” IN THE ON SAFE POSITION. OPEN THE ACTION AND MAKE CERTAIN YOUR SHOTGUN IS COMPLETELY UNLOADED. KEEP THE MUZZLE POINTED IN A SAFE DIRECTION. FAILURE TO FOLLOW THESE WARNINGS COULD RESULT IN SERIOUS INJURY OR DEATH.

Sight Adjustment

Sight Adjustment

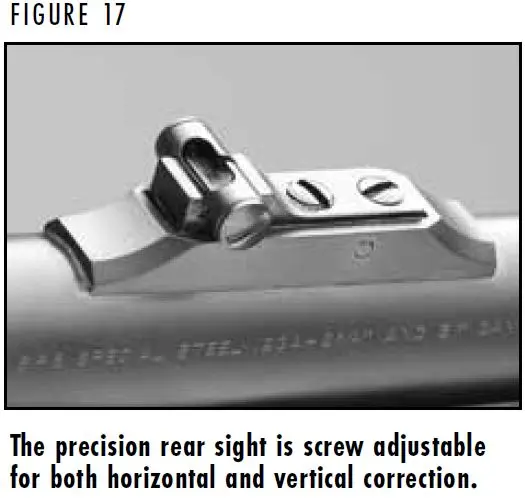

Some BPS shotguns are fitted with rifle-type open sights. The style and adjustment system may vary between models and grades. The proper procedure is to shoot a group with the sights set as they come from the factory (intermediate position on both elevation and windage), and then make incremental adjustments to move the sight blade and blade holder to position the group on your target. The following procedures are for the most common type of open sights found on BPS shotguns (Figure 17).

RIGHT OR LEFT WINDAGE ADJUSTMENTS

Horizontal adjustment is controlled by two screws located on the sides of the sight.

- To move the point of impact to the right: Loosen the screw on the right side of the sight. Then tighten the screw on the left side of the sight.

- To move the point of impact to the left: Loosen the screw on the left side of the sight and tighten the screw on the right side.

UP OR DOWN ELEVATION ADJUSTMENTS

Vertical adjustment is controlled by two screws located on top of the sight.

- To raise the point of impact: Loosen the front screw and then tighten the rear screw.

- To lower the point of impact: Loosen the rear screw and then tighten the front screw.

Magazine Cut-Off

Magazine Cut-Off

BPS Trap models feature a magazine cut-off that makes single-shot loading of the chamber possible without first loading a shell into the magazine. The magazine cut-off is located at the base of the magazine, just in front of the receiver. There are two positions on the magazine cut-off, S (single-shot) and R (repeating).

- When the magazine cut-off is in the S position, the carrier remains locked in position, preventing the shell stop from releasing a shell from the magazine into the chamber, while allowing you to easily load a shell into the chamber through the loading/ejection port. Ejection is also slowed in this position, allowing trap shooters to easily control fired hulls on ejection.

- When the magazine cut-off is in the R position, your BPS operates normally as a repeater.

WARNING: BEFORE PERFORMING CLEANING PROCEDURES, PLACE THE “SAFETY” IN THE ON SAFE POSITION. OPEN THE ACTION AND MAKE CERTAIN YOUR SHOTGUN IS COMPLETELY UNLOADED. KEEP THE MUZZLE POINTED IN A SAFE DIRECTION. FAILURE TO FOLLOW THESE WARNINGS COULD RESULT IN SERIOUS INJURY OR DEATH.

WEAR EYE PROTECTION WHEN DISASSEMBLING AND CLEANING YOUR SHOTGUN TO PREVENT SPRINGS, SPRING-LOADED PARTS, SOLVENTS OR OTHER AGENTS FROM CONTACTING YOUR EYES, RESULTING IN INJURY.

KEEP ALL AMMUNITION AWAY FROM THE CLEANING AREA. NEVER TEST THE MECHANICAL FUNCTION OF YOUR SHOTGUN WITH LIVE AMMUNITION. FAILURE TO FOLLOW THESE WARNINGS COULD RESULT IN SERIOUS INJURY OR DEATH.

NOTICE: SOME CLEANING SOLVENTS, LUBRICANTS AND OTHER STRONG CHEMICALS SUCH AS THOSE FOUND IN INSECT REPELLENTS, SUNSCREENS, ETC. MAY DAMAGE THE FINISHES OF YOUR FIREARM. USE CARE TO PREVENT CHEMICALS FROM MAKING CONTACT WITH FINISHES WHEN CLEANING YOUR FIREARM.

Cleaning and Maintenance Suggestions

Cleaning and Maintenance Suggestions

CLEANING THE BARREL

Your BPS shotgun will function better and more reliably over a longer period of time if it is properly maintained and kept clean. You should clean your shotgun after every day of shooting, and more often if it becomes excessively dirty. The barrel should be cleaned and the action wiped clean and oiled after every day of shooting.

Normal maintenance can be accomplished with the barrel still attached to the receiver (oiling and wiping down). More thorough cleaning requires removal of only the barrel from the receiver (cleaning the barrel).

If a malfunction occurs, perform a thorough cleaning to see if it solves the problem before seeking the services of a Browning Recommended Service Center, the Browning Service Facility in Arnold, Missouri, or a qualified gunsmith.

1. Place the “safety” in the on safe position. Open the action and inspect the chamber and magazine to make certain they do not contain any shells. Keep the muzzle pointed in a safe direction.

2. Remove the barrel as explained under the “Disassembly” section.

3. Using a shotgun cleaning rod with a slotted tip or cleaning jag and a patch large enough for a snug fit in the bore, insert the rod and a lightly oiled patch into the breech end of the barrel and run it back and forth through the bore several times. Remove and wipe the choke tube, threads and barrel threads with a nylon brush and lightly oil.

Browning offers a complete line of products to make cleaning your firearm fast and easy. Be sure to follow all instructions when using any product to clean your firearm.

4. Inspect the bore from both ends for leading and plastic residue that often remain in the bores from the shot cups in modern shells. Leading and plastic residue will appear as longitudinal streaks and are usually more predominant near the muzzle and just forward of the chamber. A normal amount of either is common and not serious.

5. If leading or plastic residue seems excessive you can remove it by brushing the bore with a brass brush. Soak the brush or spray the bore with a powder solvent first. Scrub until clean. To prevent bristles from breaking off, push the brush fully through the barrel each time before pulling it back through.

WARNING: MOST SOLVENTS ARE HIGHLY FLAMMABLE. WEAR EYE PROTECTION AND PRACTICE APPROPRIATE SAFETY MEASURES WHEN WORKING WITH SOLVENTS TO AVOID SERIOUS INJURY.

6. After all leading and plastic residues have been removed, run a clean, dry patch through the bore. Follow this with a final, lightly oiled patch.

7. Reassemble the shotgun and wipe all exposed metal surfaces with an oiled cloth making sure to wipe away all finger marks where moisture could accumulate.

8. Inspect the barrel and chamber to be certain no patches have inadvertently been left in them. Remove any that remain.

9. Lightly oil your firearm at the points described under the “Periodic Oiling” section below. Regular, light oiling is extremely important to the durability and reliable operation of your shotgun.

10. The wood surfaces can also be wiped with a quality, lightweight gun oil or they can be polished with any quality furniture wax (but not both).

NOTICE: NEVER ATTEMPT TO TAKE YOUR FIREARM APART FURTHER THAN EXPLAINED IN THIS OWNER’S MANUAL. YOUR FIREARM IS A SPECIALIZED, FINELY FITTED MECHANISM. YOU MAY PERMANENTLY DAMAGE IT BY ATTEMPTING TO DISASSEMBLE THE INNER MECHANISM ASSEMBLIES. IF FURTHER DISASSEMBLY FOR SERVICE OR CLEANING IS REQUIRED, TAKE YOUR FIREARM TO A QUALIFIED GUNSMITH, OR CONTACT OUR ARNOLD, MISSOURI SERVICE FACILITY AS EXPLAINED UNDER THE “SERVICE OR REPAIR” SECTION.

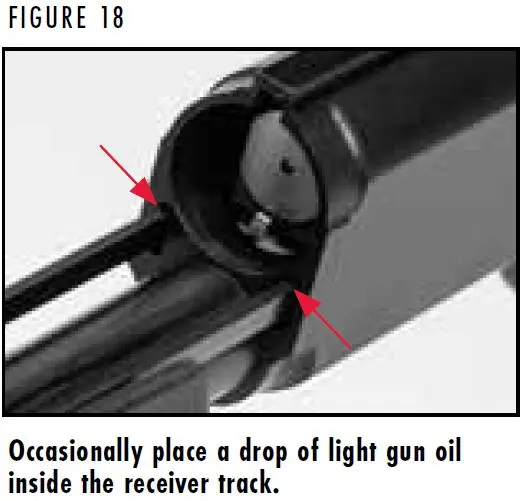

PERIODIC OILING

The metal parts of a firearm should receive a light film of oil after the firearm has been exposed to weather or handling. Occasionally a small drop of light gun oil may be placed inside the receiver track on which the breech block and action bars ride during operation (Figure 18). This will help relieve friction and ensure smooth operation.

NOTICE: DO NOT PLACE LARGE QUANTITIES OF OIL INTO THE ACTION. EXCESS OIL WILL RUN BACK INTO THE WOOD OF THE STOCK SOFTENING THE WOOD, WITH CONSEQUENTIAL LOOSENING OF THE STOCK.

Barrel Porting

Barrel Porting

Some BPS models feature a ported barrel that reduces recoil and muzzle jump. Reducing recoil not only increases comfort when shooting, but increases accuracy because it is easier to pick-up the second clay target faster due to decreased recovery time following the first shot. Carbon can build up in the ports after shooting. To clean them, use a good quality powder solvent and pipe cleaners to scrub away debris from the ports.

Maintenance of Oil Finish Stocks

Maintenance of Oil Finish Stocks

Keeping the oil-finished wood surface on your firearm looking its best requires only a small amount of maintenance. When the surface becomes spotted or dull, the affected area(s) can be treated using rubbing alcohol on a soft, lint free cloth and allowed to dry. A small amount of a linseed oil-based finish, such as Watco® Danish Oil Finish, Deft® Danish Oil Finish, or Formby’s® Tung Oil Finish should then be applied to the surface of the wood with a soft, lint free cloth according to the manufacturer’s instructions. To treat the checkering, a small amount of oil-based finish can be applied and then distributed evenly using a toothbrush or other soft bristled brush.

Models with Special Finishes

Models with Special Finishes

As with any firearm, the only way to preserve its pristine condition and collector appeal is to never handle or fire it, which in turn would deprive you of much of the enjoyment that comes with owning a fine Browning firearm.

While special finishes such as engraving and gold plating greatly enhance the aesthetic appeal of your shotgun, please be aware that they are no more durable, and in some cases may even be slightly less durable than more common firearm finishes.

As you use your shotgun, you can expect special finishes to wear in much the same manner as any other firearm finish. These marks are the honest product of the hours spent enjoying your firearm and each scuff and scratch will probably have a good story to go along with it.

SERVICE OR REPAIR

SERVICE OR REPAIR

If your firearm should require service or repairs, we suggest you first contact a local recommended Browning Firearms Service Center.

To locate a service center visit browning.com, contact our Customer Service Department or your Browning firearms dealer for the address of the Service Center nearest you. Otherwise, you may send your firearm directly to our Service Department in Arnold, Missouri.

Parts listings, Firearm Service Center lists, service procedures, service/repair form and general product information are also found on the internet at browning.com. For technical questions about your firearm or service, contact:

United States customers contact:

Browning Firearm Status and

Technical Service

3005 Arnold Tenbrook Rd

Arnold, MO 63010-9406

Phone: (800) 322-4626

Canadian customers contact:

Browning Canada Sports Ltd/Ltée

5583 Chemin St-François

St-Laurent, Quebec H4S 1W6

Phone: (514) 333-7261

When returning your firearm for servicing, you must do the following:

1. Be sure it is completely unloaded.

2. Remove any optics, optic mounts or other accessories.

3. Package it securely in a cardboard container.

4. Enclose the service/repair form available at browning.com or a letter that clearly describes the trouble experienced, the ammunition used and the repairs desired. Also include your name, e-mail address (if possible) and a daytime phone number where you can be reached.

5. Never return ammunition with your firearm. It is against postal and most commerce regulations.

BROWNING.COM

US: Morgan, Utah 84050-9326

CANADA: Browning Canada Sports Ltd/Ltée, St-Laurent, Quebec H4S 1W6

INTL: Parc Industriel des Hauts-Sarts, B-4040 Herstal, Belgium

22-BFA-206